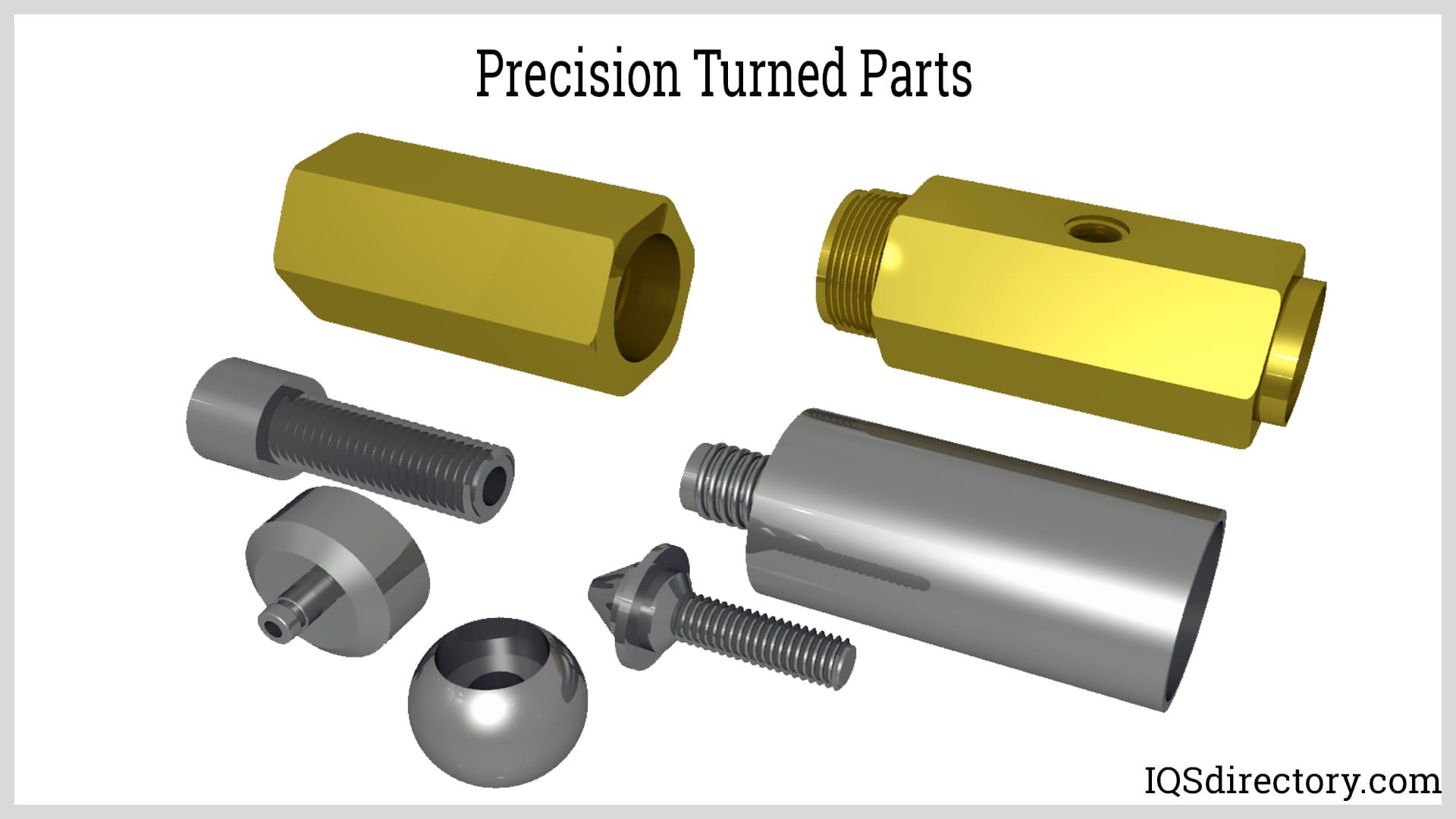

Complex pieces that are often cylindrical and threaded are called screw machine parts. These parts are employed in the production of an infinite number of products as well as for building and maintenance purposes.Read More…

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

At Edward Koehn Co, we are dedicated to delivering reliable and efficient solutions to our clients. With state-of-the-art equipment, experienced technicians, and a commitment to continuous improvement, we strive to exceed customer expectations and drive success in every project.

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Screw Machine Part Manufacturers

Screw Machine Products: Precision Manufacturing for High-Volume Production

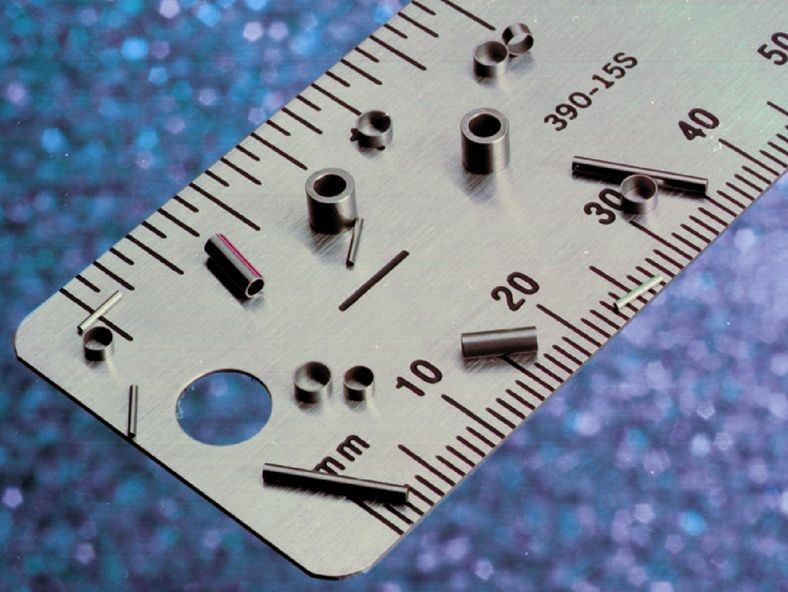

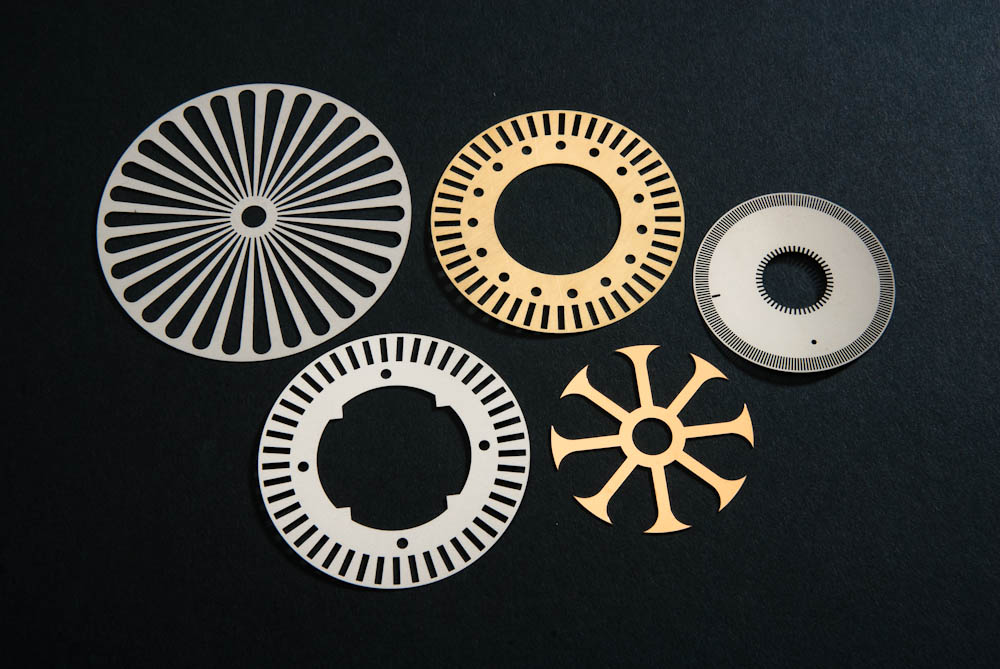

Screw machines are a cornerstone of precision manufacturing and high-speed production in the metalworking industry. Capable of producing high volumes of complex parts with exceptional accuracy, these machines are essential for a wide range of industries, including automotive, aerospace, electronics, medical devices, and more. Screw machine products—ranging from small fasteners and fittings to intricate custom components—are ubiquitous in modern manufacturing, supporting applications where consistency, tight tolerances, and rapid turnaround are critical.

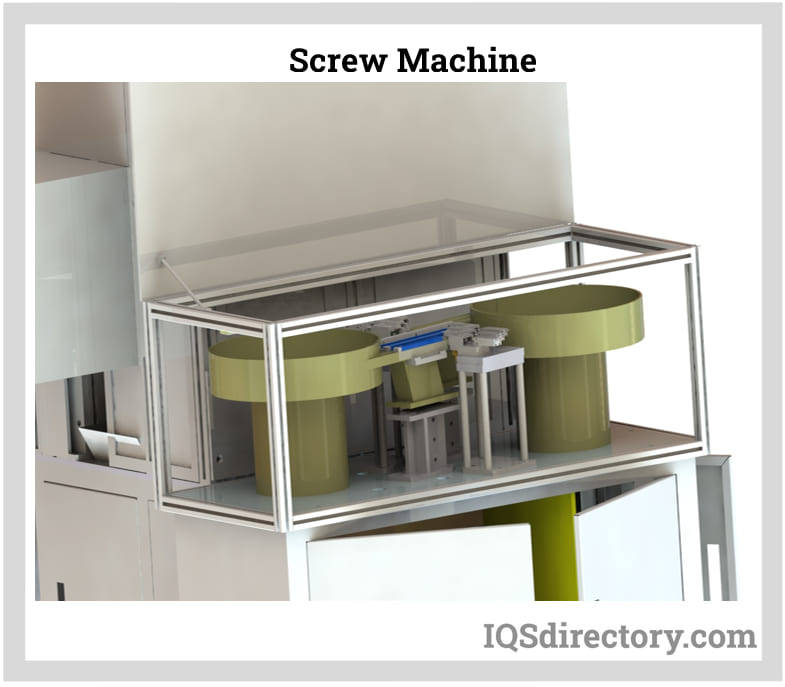

They can create items at high speeds and may have numerous spindles, with a six-spindle machine being the most typical arrangement. A family of automatic lathes for tiny to medium-sized parts is known as a screw machine product. Since they no longer produce screws or screw anything into place, the moniker, "screw machine," is thought to be a little deceptive.

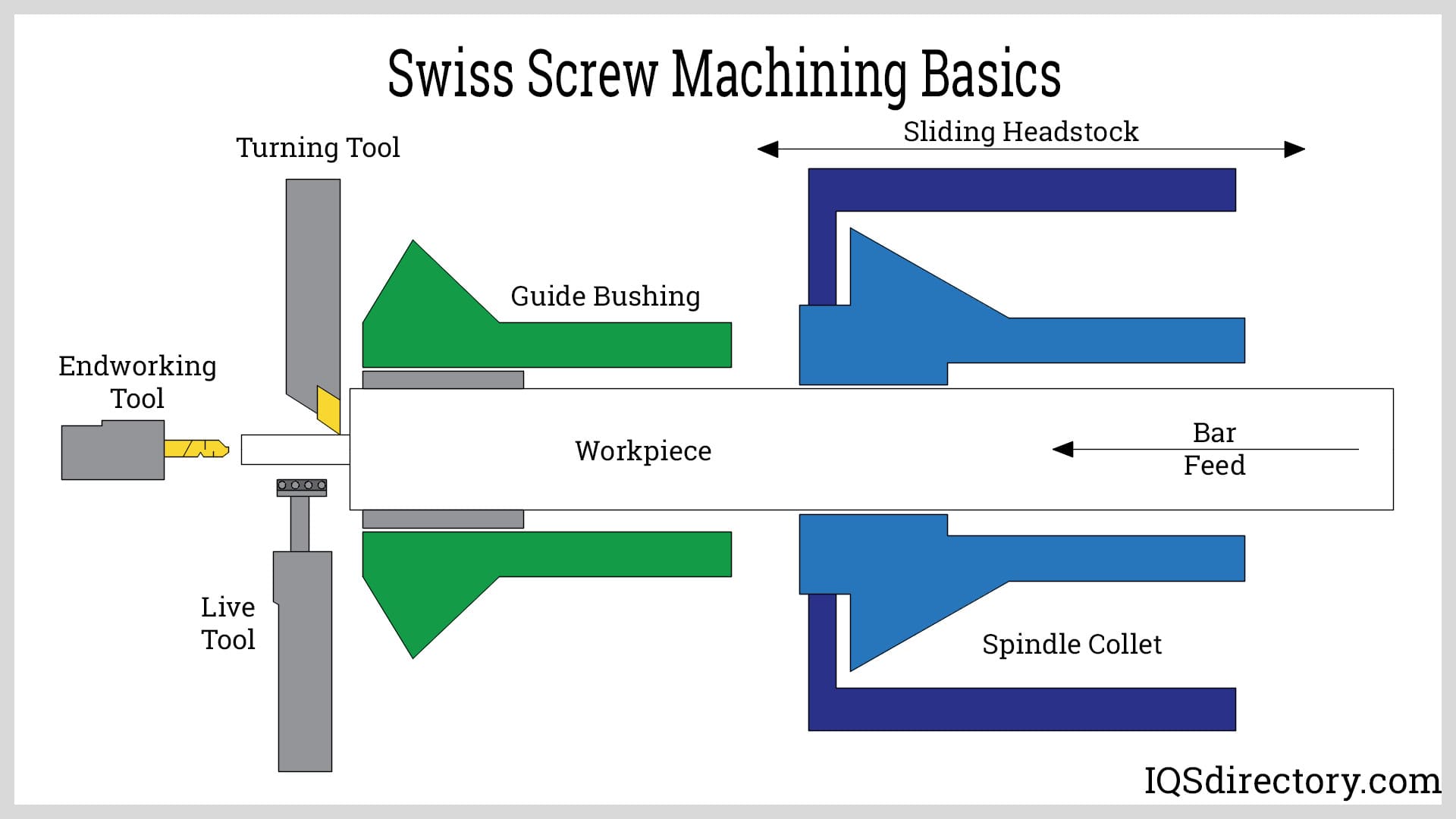

Instead of "screwing" components, screw machines rotate on a revolving lathe, efficiently shaving or cutting metal to precise dimensions. A revolving component called a disc cam—integral to many screw machines—converts rotary motion into linear motion or vice versa, utilizing one or more spindles for simultaneous operations. Modern screw machines operate with close spindle collets, which help reduce or eliminate deflected debris, enhancing both part quality and operator safety.

Types of Screw Machines: Automatic, Swiss, and CNC Screw Machines

In today's market, screw machines come in several varieties, each suited for specific production requirements, materials, and tolerances. The primary categories include:

- Automatic Screw Machines: Operate using mechanical cams and levers for continuous production. Ideal for medium- to large-volume runs of relatively simple parts, these machines are highly efficient and cost-effective for repeat jobs. They excel in manufacturing items such as bushings, spacers, standoffs, and fasteners.

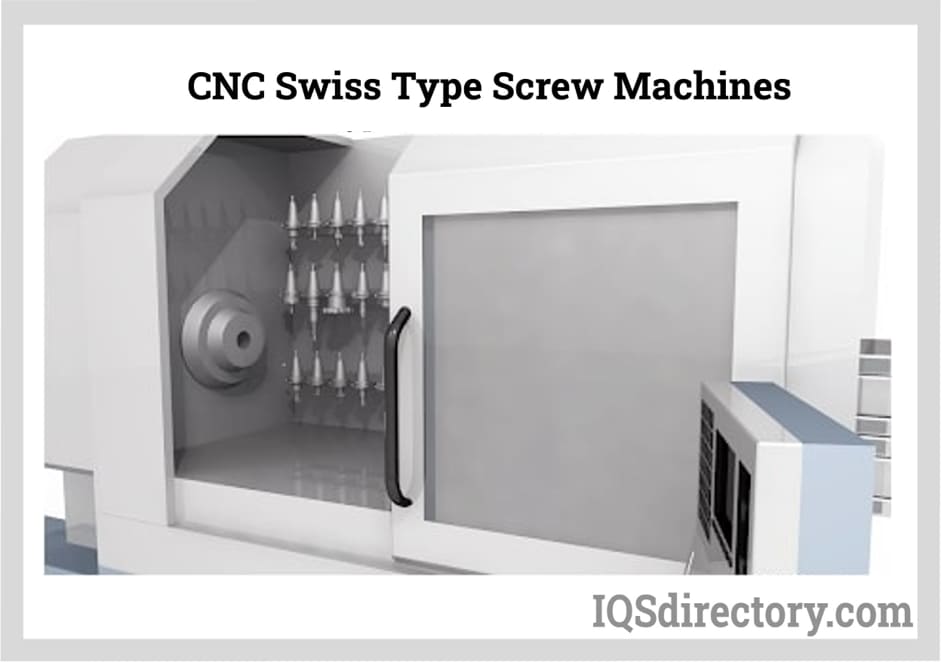

- Swiss Screw Machines: Also known as Swiss-type lathes, these employ a sliding headstock and fixed guide bushing for manufacturing slender, high-precision parts. Swiss screw machines are renowned for producing tight-tolerance components for industries like medical device manufacturing, electronics, and watchmaking.

- CNC Swiss Screw Machines: An evolution of the traditional Swiss lathe, CNC Swiss machines use computer numerical control (CNC) systems for unparalleled versatility, automation, and precision. By utilizing multiple programmable axes, CNC Swiss lathes can create extremely complex geometries with minimum human intervention. They are the preferred choice for parts requiring intricate features, fine threads, and consistent quality across long production runs.

A disc cam is used in automatic Swiss screw machines to rotate tools in the direction of the workpiece area, which is fixed in place by a number of spindle collets arranged side by side. Computer precision parts can be produced with numerically-controlled machines by using a CNC unit to operate the tools. Swiss screw CNC machines, commonly referred to as CNC lathes, provide numerous axes of motion for quick and precise results.

Although they can be labor-intensive to set up properly, screw machines—both automatic and CNC-driven—are economical when producing numerous pieces. They frequently aren't the best option for sporadic prototyping. However, they are a flexible option when making parts out of many sorts of metals because of the large range of metals they work with.

Key Applications and Industries for Screw Machine Products

Screw machine products are essential in industries that demand consistently high quality, tight tolerances, and cost-effective production at scale. Common applications and sectors include:

- Automotive: Production of precision pins, bushings, connectors, and fittings for engines, transmissions, and braking systems.

- Aerospace: Manufacture of lightweight, high-strength fasteners, bushings, and custom components for aircraft and spacecraft systems.

- Medical Devices: Creation of surgical instruments, orthopedic pins, dental implants, and other medical-grade components requiring exceptional precision and biocompatibility.

- Electronics: Fabrication of miniature connectors, contact pins, terminal blocks, and housings for circuit boards and electronic assemblies.

- Industrial Machinery: Production of bushings, spacers, standoffs, threaded inserts, and custom machine components used in automation and assembly lines.

- Consumer Products: Manufacture of precision hardware for appliances, locks, plumbing, and furniture.

Differences Between Mechanical and CNC Screw Machining

When evaluating screw machining solutions, understanding the distinctions between mechanical screw machines and CNC screw machines is crucial for making an informed purchasing decision. Here’s a detailed comparison:

- Production Volume: Traditional mechanical screw machines are optimized for high-volume production. Their rapid cycle times and simultaneous multi-spindle operations make them ideal for manufacturing thousands or millions of identical parts cost-effectively.

- Setup and Flexibility: Mechanical screw machines require skilled setup and manual adjustment of cams and tooling—efficient for repeat orders but less flexible for design changes or small-batch production. By contrast, CNC screw machines are programmed digitally, enabling rapid changeovers and seamless production of complex, customized parts in smaller quantities.

- Precision and Tolerances: CNC screw machines excel in delivering tighter tolerances and more intricate features due to advanced control systems, servo motors, and multi-axis movement. Mechanical machines maintain high precision for standard geometries but may be less suitable for highly detailed or variable designs.

- Cost Considerations: For large production runs, mechanical screw machines often offer lower per-part costs due to sheer speed and efficiency. However, for prototyping, small batches, or parts requiring frequent revisions, CNC screw machines are more cost-effective—reducing labor, scrap, and downtime.

- Automation and Integration: CNC screw machines can be integrated with robotic loaders, automated inspection, and in-line measurement systems, supporting Industry 4.0 and smart manufacturing initiatives. Mechanical systems, while robust, offer less automation potential.

Screw machining achieves precision and tolerances that are difficult to match. Other metal fabrication and forming techniques rarely produce items with a screw machine's level of excellence. Screw machines are perhaps the best tools available for creating turned pieces.

Benefits of CNC Screw Machines and Multi-Spindle Technology

Modern CNC screw machines offer numerous advantages for manufacturers seeking efficiency, accuracy, and scalability. Key benefits include:

- Exceptional Precision: CNC Swiss screw machines deliver accuracy within 0.0002 to 0.0005 inches, enabling the production of micro-sized parts and components with complex features. This makes them ideal for critical applications in medical, aerospace, and electronics industries.

- High-Speed Manufacturing: With spindle speeds up to 10,000 RPM, CNC screw machines can rapidly turn and mill parts, significantly reducing cycle times and increasing throughput. Multi-spindle machines multiply productivity by enabling simultaneous operations—sometimes producing up to six identical parts at once.

- Reduced Waste and Material Costs: Advanced CNC programming and toolpath optimization minimize material waste, lowering raw material costs and supporting sustainable manufacturing initiatives.

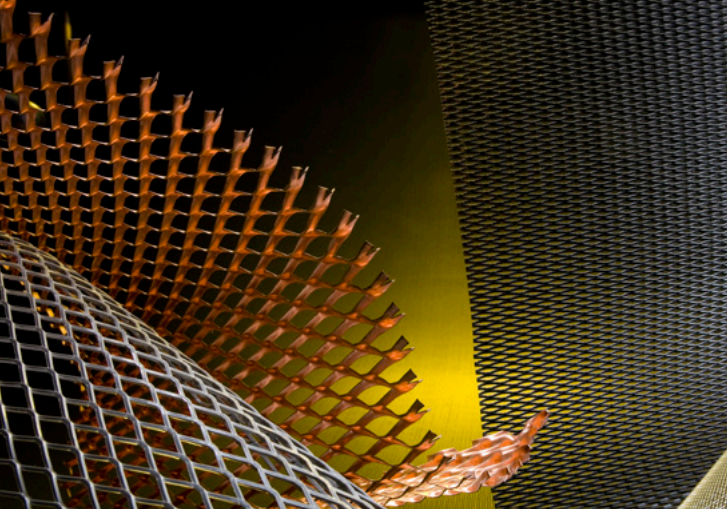

- Versatility in Materials: CNC screw machines can process a wide range of metals and alloys, including stainless steel, brass, aluminum, titanium, and specialty materials. This flexibility allows manufacturers to meet diverse engineering requirements and industry standards.

- Automation and Unattended Operation: CNC screw machines can operate around the clock with minimal supervision, increasing factory utilization and reducing labor costs. Integration with bar feeders, part catchers, and in-process inspection tools further enhances productivity.

- Consistent Quality: Digital controls and real-time monitoring ensure each part meets strict dimensional and surface finish requirements, minimizing defects and rework.

- Compact Footprint and Energy Savings: Multi-spindle machines combine multiple operations within a single footprint, saving valuable floor space and reducing energy consumption. This efficiency can yield significant cost savings over time.

Why Choose CNC Screw Machining Over Conventional Turning?

Are you evaluating whether CNC screw machining is right for your next project? Consider these decision factors:

- Does your component require complex features, fine threads, or ultra-tight tolerances?

- Do you need to produce high volumes quickly, or are you seeking flexibility for small batch runs?

- Is material waste and cost reduction a priority in your manufacturing process?

- Are you looking to automate part production for increased consistency and reduced labor costs?

If you answered "yes" to any of these, CNC Swiss screw machining is likely the best solution for your requirements. For more insight, compare CNC lathes vs. conventional turning centers or explore automatic screw machines for different production scenarios.

Common Questions About Screw Machine Products and Suppliers

- What is a screw machine product? A screw machine product is a precision-turned component manufactured on an automatic or CNC screw machine. These products are commonly used in automotive, aerospace, medical, electronics, and industrial applications due to their accuracy and repeatability.

- How do I choose the right screw machine for my part? Consider factors such as production volume, part complexity, material type, required tolerances, and lead time. For high-volume, simple parts, mechanical screw machines may be ideal. For complex geometries and short runs, CNC Swiss screw machines offer superior flexibility and precision.

- Which materials can be machined? Screw machines can process a wide array of materials, including stainless steel, brass, aluminum, titanium, copper, and engineering plastics. Consult with your supplier to match material selection with your application’s requirements.

- What tolerances can be achieved? Modern CNC screw machines regularly achieve tolerances as tight as ±0.0002 inches, suitable for critical aerospace and medical components.

- What is the typical lead time for screw machine parts? Lead times vary by volume, complexity, and supplier capacity. CNC machines can expedite prototyping and small batches, while mechanical screw machines are best for high-volume, repeat production.

How to Select the Best Screw Machine Parts Supplier

Finding the right screw machine parts supplier is essential for ensuring project success, cost savings, and timely delivery. Here are steps to identify the most qualified partner:

- Compare Supplier Capabilities: Evaluate at least 4 to 5 companies using our comprehensive list of screw machine parts suppliers. Examine each supplier’s specialties, equipment, certifications, and experience with similar part geometries and materials.

- Review Business Profiles: Each screw machine parts company has a detailed business profile page highlighting their core competencies, machining capabilities, secondary operations (such as deburring, heat treating, and plating), quality assurance processes, and industry certifications (ISO, AS9100, etc.).

- Request Quotes and Technical Guidance: Use the contact forms to request quotations, lead times, and technical recommendations. Ask about their quality control procedures, sample part inspection, and ability to handle design modifications or tight delivery schedules.

- Leverage Our Website Previewer: Quickly preview supplier websites to gauge professionalism, technology investments, and customer testimonials. This helps you shortlist the most reputable and capable firms for your needs.

- Submit a Unified RFQ: Use our simple Request for Quote (RFQ) form to contact multiple screw machine part companies simultaneously—streamlining the sourcing process and encouraging competitive bids.

- Assess Customer Service and Communication: Prompt, clear communication and willingness to address questions or concerns are indicators of a reliable supplier.

To make sure you have the most positive outcome when purchasing screw machine parts from a screw machine parts supplier, it is important to compare at least 4 to 5 companies using our list of screw machine parts suppliers. Each screw machine parts company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each screw machine parts company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple screw machine part companies with the same form.

Ready to Get Started? Find a Screw Machine Products Supplier Now

Whether you require precision-turned parts for a one-off prototype or ongoing high-volume production, our curated directory of screw machine products suppliers empowers you to source the best partner for your needs. Use our search tools to:

- Find suppliers based on geography, industry specialization, or material capabilities.

- Compare supplier ratings, certifications, and case studies to assess quality and reliability.

- Request information or quotes directly from multiple suppliers for side-by-side comparison.

- Explore detailed guides and resources on screw machine parts, CNC Swiss machining, and material selection to inform your purchasing decisions.

Frequently Searched Screw Machine Topics

- What are the advantages of multi-spindle screw machines for high-volume production?

- How do CNC Swiss lathes compare to traditional turning centers for complex parts?

- What secondary operations (deburring, threading, heat treating, plating) are available for screw machine products?

- Which industries most benefit from precision screw machine components?

- How does screw machining impact project lead times and cost efficiency?

- What are the latest innovations in screw machine technology and automation?

- What quality certifications should I look for in a screw machine parts supplier?

Additional Resources

- Screw Machine Buyer's Guide

- CNC Swiss vs. Traditional Turning: Which Is Right for Your Project?

- Metal Selection for Screw Machining

- Quality Assurance in Screw Machine Products

- Industry Applications of Screw Machine Parts

- Submit a Request for Quote (RFQ)

For more information about screw machine products, CNC Swiss machining, or to connect with trusted suppliers, contact us today or explore our comprehensive directory of screw machine parts manufacturers.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

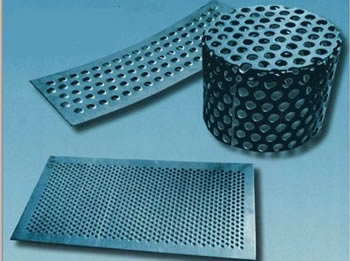

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

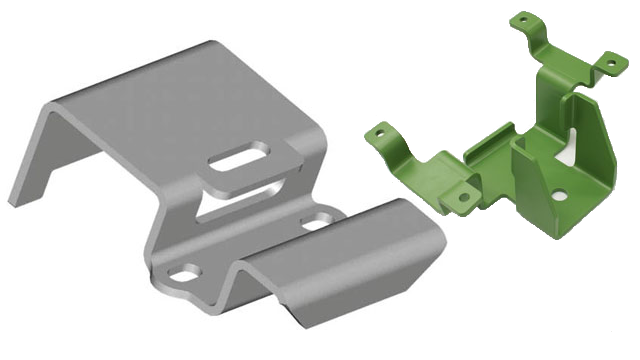

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

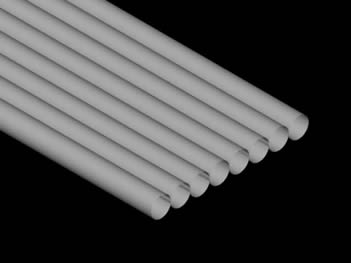

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services