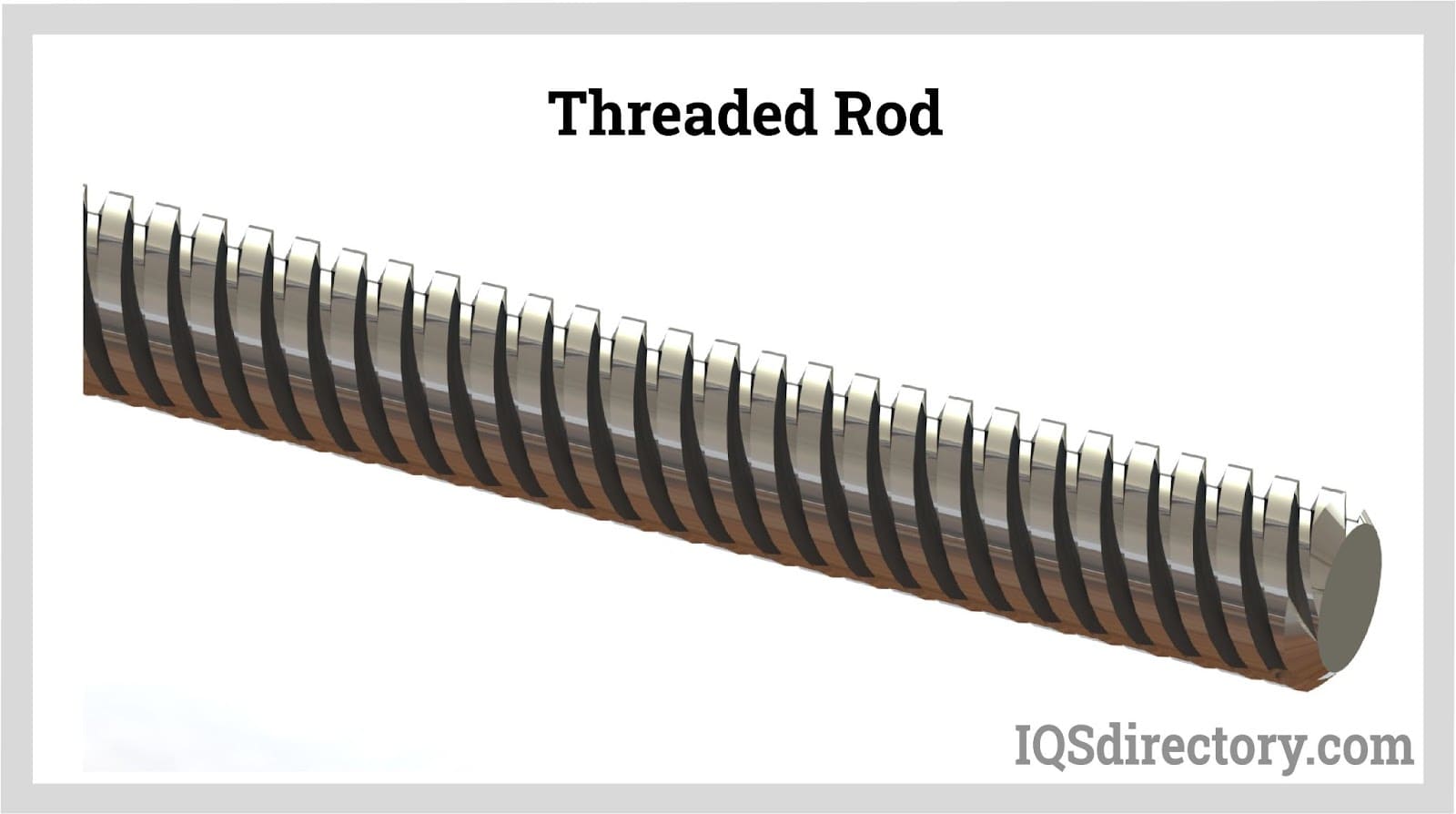

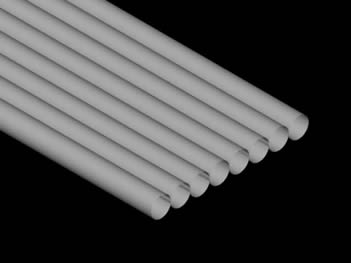

As the name implies, a threaded rod is a metal rod that has threads running the entire length of it. These rods have a screw-like appearance, although they are often longer and thicker than a typical screw. Unlike screw-on bolts, threaded rods do not have heads or washers, and they frequently have the same diameter throughout their entire length. Read More…

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

At Edward Koehn Co, we are dedicated to delivering reliable and efficient solutions to our clients. With state-of-the-art equipment, experienced technicians, and a commitment to continuous improvement, we strive to exceed customer expectations and drive success in every project.

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Threaded Rod Manufacturers

Threaded rod, sometimes referred to as a stud, all-thread, or threaded bar, is a versatile fastener widely used in construction, manufacturing, and industrial applications. Typically, threaded rods are fabricated from carbon-coated steel, zinc-plated steel, or stainless steel. These robust materials provide essential strength, corrosion resistance, and reliability, making threaded rods a preferred choice for joining and securing materials. The threading along the rod enables bolts, nuts, washers, and other fasteners to be attached, accommodating a variety of building and engineering applications.

Threaded rods are commonly used to create secure connections between two separate materials—such as concrete to structural steel, metal-to-metal, or wood-to-metal connections. This adaptability has made threaded rods indispensable across commercial, industrial, and residential projects. Are you searching for the right type of threaded rod for your application? Explore our guide to choosing the best threaded rod manufacturer for your needs.

How Threaded Rods are Made

Manufacturing high-quality threaded rods begins with selecting the appropriate base material—usually round bar stock of the desired grade and diameter. Common materials include mild steel, high-tensile steel, galvanized steel, and stainless steel (such as 304 and 316 grades). The chosen material directly impacts the rod’s strength, corrosion resistance, and suitability for demanding environments such as marine, chemical, or structural settings.

To mass-produce threaded rods of standard diameters and grades, manufacturers employ a thread rolling process. In this automated procedure, the round bar is fed through a pair of hardened steel roller dies precisely spaced to imprint the desired thread form onto the bar. The intense pressure exerted by the rollers plastically deforms the metal surface, forming continuous, high-strength threads along the length of the rod. Thread rolling is preferred for its speed, consistency, and its ability to improve fatigue resistance and mechanical properties of the finished rod.

After threading, rods are typically cut to specified lengths using automated saws, and their ends are beveled or chamfered to create a smooth, finished surface. This not only enhances safety during handling and installation but also allows for easier engagement with nuts or coupling connectors.

For customized or non-standard threaded rod sizes and thread patterns, thread cutting is used instead. In this method, a precisely cut rod is passed through a threading machine or lathe that removes material to generate the threads. While this technique is more labor-intensive and costly than rolling, it enables the production of special thread profiles, such as Acme threads, fine threads, or left-hand threads, tailored to unique application requirements.

Depending on the application, threaded rods may undergo additional surface treatments or coatings—such as zinc plating, hot-dip galvanizing, or black oxide coating—to improve corrosion resistance, durability, and appearance. Stainless steel threaded rods, on the other hand, offer inherent corrosion resistance and are ideal for harsh or outdoor environments.

Applications of Threaded Rods

Wondering where threaded rods are commonly used or how they can benefit your next project? Threaded rods are essential fasteners across a wide spectrum of industries due to their versatility, strength, and ease of installation. Here’s a detailed look at key threaded rod applications:

- Construction and Structural Engineering: Threaded rods serve as anchor bolts, tie rods, and bracing components in concrete, masonry, and steel structures. Contractors rely on them for securing beams, columns, and heavy equipment. Their ability to provide a continuous threaded length allows for flexible positioning and adjustment during installation.

- Mechanical and Industrial Manufacturing: In manufacturing and fabrication, threaded rods are used to assemble machinery, secure equipment, and join components. They are compatible with a wide range of fasteners—nuts, washers, couplings—making them ideal for modular assembly lines and heavy-duty fixtures.

- HVAC, Plumbing, and Electrical Installations: Threaded rods are frequently used for suspending piping, ductwork, lighting fixtures, cable trays, and electrical panels from ceilings or structural supports. Their adjustability and strength make them a standard solution for contractors working on commercial and industrial building systems.

- Automotive and Transportation: Automotive repair shops use threaded rods for chassis repair, suspension work, and machinery assembly. In railways and bridges, extra-long threaded rods act as anchor bolts and structural connectors required for high-load applications.

- Furniture Manufacturing and DIY Projects: Metalworkers and woodworkers use threaded rods to create rigid joints in furniture, shelving, and custom fixtures. Their ease of cutting, bending, and threading with standard tools appeals to hobbyists and professionals alike.

- Marine, Oil & Gas, and Chemical Industries: Stainless steel threaded rods, with their superior corrosion resistance, are chosen for offshore platforms, processing plants, and environments exposed to moisture, chemicals, or saltwater.

- Specialty and Custom Applications: When unique thread profiles (such as left-handed threads or Acme threads) are needed to prevent loosening from vibration or to transmit motion, custom-cut threaded rods provide the required performance and safety.

Still unsure how to select the best threaded rod for your application? See our comprehensive buyer’s guide below.

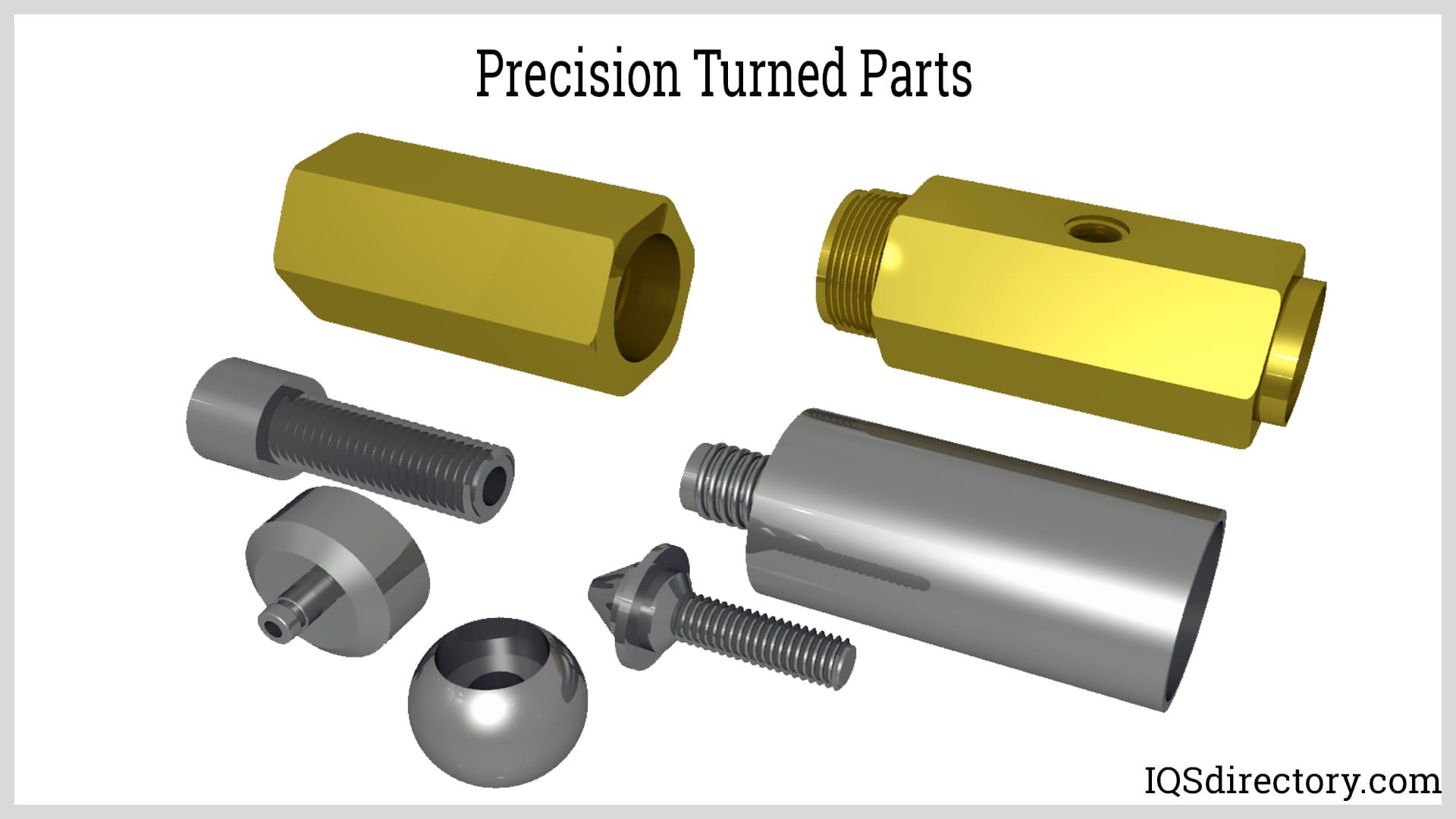

Types of Threaded Rods and Thread Forms

When choosing a threaded rod, understanding the different thread types and rod configurations is essential to ensure safe, effective installation and long-term performance. Threaded rods are available in various diameters, lengths, thread pitches, and materials. Key thread forms include:

- Right-Hand Threads: The most common type—tighten with a clockwise rotation. Suitable for most general fastening applications.

- Left-Hand Threads: Tighten counterclockwise, used where vibration or rotation might loosen right-handed threads (e.g., rotating machinery, automotive applications).

- Coarse Threads (UNC): Greater resistance to stripping and easier to assemble/disassemble—ideal for general construction and wood applications.

- Fine Threads (UNF): Enhanced load-carrying capacity and vibration resistance—used in automotive, aerospace, and machinery.

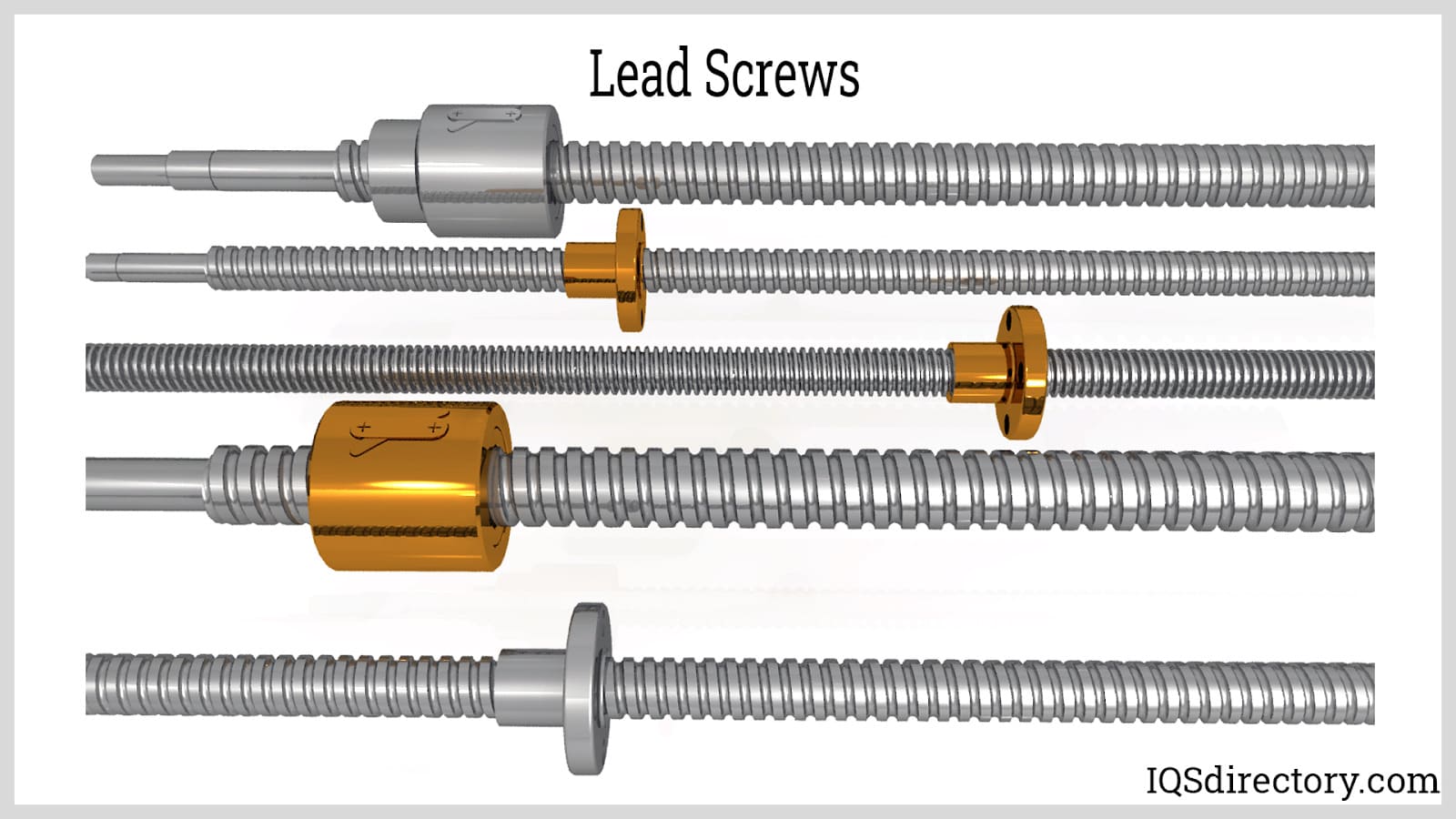

- Acme Threads: Have a square, flat crest—commonly used in power transmission, lead screws, and heavy-duty mechanical assemblies.

- Fully Threaded vs. Partially Threaded Rods: Fully threaded rods allow for nuts to be positioned anywhere along the length, while partially threaded rods provide added shear strength at the unthreaded section.

Not sure which thread form is best for your project? Ask our experts or request a quote for technical advice.

Advantages of Using Threaded Rods

- High Strength and Structural Integrity: Threaded rods provide excellent tensile strength—making them suitable for high-load, high-stress environments. Structural engineers and architects use them to ensure stability and safety in buildings, bridges, and heavy equipment installations.

- Corrosion Resistance and Durability: Stainless steel and galvanized rods resist rusting, oxidation, and degradation even in harsh outdoor, marine, or chemical environments. Choosing corrosion-resistant materials can reduce long-term maintenance costs and extend the service life of your project.

- Versatility and Adaptability: Threaded rods are compatible with a wide range of standard nuts, washers, and connectors, allowing for quick assembly, disassembly, or adjustment. This makes them invaluable for temporary structures, repairs, and modular systems.

- Customizable Lengths and Sizes: Available in various diameters (from M6, 1/4", up to M36 and larger) and lengths (1 meter, 3 feet, 6 feet, or custom), threaded rods can be easily cut to length or extended with coupling nuts, offering maximum flexibility on-site.

- Cost-Effectiveness: Standard threaded rods are a low-cost solution for many fastening and anchoring needs. Their widespread availability and compatibility with common fasteners streamline procurement and reduce project costs.

Are you evaluating the benefits of stainless steel versus zinc-plated threaded rods? Contact us for a material comparison and expert recommendations.

Choosing the Correct Threaded Rod Manufacturer

Selecting the right threaded rod supplier or manufacturer is a critical step in ensuring quality, reliability, and value for your project. Here are key factors to consider when sourcing threaded rods:

- Product Range & Customization: Does the manufacturer offer the full spectrum of diameters, grades, thread forms, and surface finishes you need? Do they support custom orders for special lengths, threading, or materials?

- Quality Assurance & Certifications: Reputable suppliers follow strict quality control processes and may hold certifications such as ISO 9001, ASTM, or DIN standards. These credentials ensure consistent product performance and traceability.

- Material Sourcing & Traceability: High-quality threaded rods begin with high-grade raw materials. Ask about the traceability of their steel, stainless, or specialty alloys to guarantee performance in your application.

- Lead Time & Availability: Fast, reliable delivery is crucial for keeping your project on schedule. Check stock levels, production capacity, and shipping policies before placing an order.

- Technical Support & Customer Service: Can the manufacturer provide engineering support, technical drawings, or installation guidance? Responsive customer service can resolve issues quickly and answer questions about product selection and use.

To ensure you get the best results when purchasing threaded rods, compare at least five manufacturers using our curated list of leading threaded rod companies. Each manufacturer profile highlights their capabilities and areas of expertise; use our direct contact forms to request quotes, technical data sheets, or product samples. Not sure where to start? Use our patented website previewer to review each company’s offerings, then submit a single RFQ form to contact multiple suppliers at once.

Frequently Asked Questions About Threaded Rods

- What sizes of threaded rod are available?

Threaded rods are commonly available in diameters ranging from M6 and 1/4" up to M36 and 2". Standard lengths include 1 meter, 3 feet, 6 feet, and custom-cut options. - How do I choose between stainless steel, zinc-plated, or galvanized threaded rods?

Stainless steel rods are ideal for corrosive or outdoor environments, while zinc-plated and galvanized rods offer cost-effective corrosion protection for indoor or low-moisture applications. - Can threaded rods be cut to length on-site?

Yes. Threaded rods can be easily cut using hacksaws, angle grinders, or rod cutters. Be sure to chamfer or deburr the cut ends for safe installation. - Are threaded rods suitable for high-strength structural connections?

Absolutely. Choose high-tensile or structural-grade rods (e.g., ASTM A193, A307) for demanding load-bearing or structural applications. - What are coupling nuts and how are they used with threaded rods?

Coupling nuts are long, internally threaded nuts used to join two lengths of threaded rod, enabling the assembly of extra-long tie rods or anchors. - What is the difference between fully threaded and partially threaded rods?

Fully threaded rods have threads along their entire length, offering maximum flexibility. Partially threaded rods feature an unthreaded shank for added strength where shear loads are highest.

Ready to Source Threaded Rods for Your Project?

Whether you are a contractor, engineer, procurement specialist, or DIY enthusiast, finding the right threaded rod can make a significant difference in the success and longevity of your project. Our extensive network of threaded rod manufacturers and suppliers offers a comprehensive selection of products, technical support, and fast shipping to meet your needs.

Have a technical question? Need a custom quote? Contact us today to get expert recommendations tailored to your application, or browse our supplier profiles to compare prices, capabilities, and lead times.

Looking for more information? Explore our applications section to see how threaded rods are used in your industry, or check our buying guide for tips on selecting the right product and supplier.

Invest in quality threaded rods and trusted suppliers to ensure safety, performance, and value—no matter the complexity or scale of your project.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

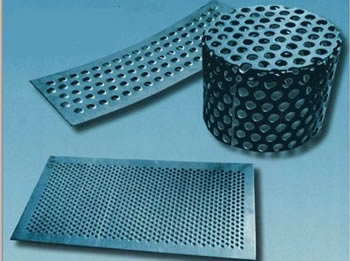

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

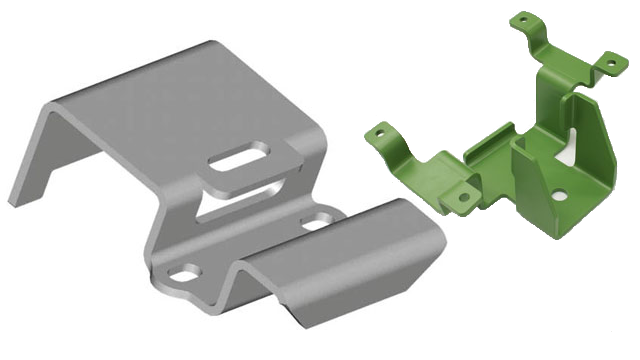

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services